This site is designed & maintained by ACS-

Unit C3, Dekema Park, 284A Dekema Rd, Wadeville, Germiston,1422

Tell: 011 865 4347

Cell: 082 925 1497

Mail: gasketman@mweb.co.za

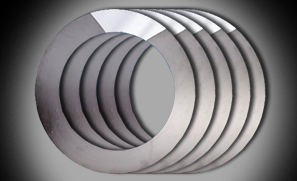

A solid metal ring.

Specifications

The solid metal gasket provides an excellent mechanical joint and has gained universal acceptance

in the oil, petroleum and chemical processing industries where high mechanical and thermal

performance is required.

The type ‘R' oval configuration is the original ring joint design and was

followed by the type ‘R”octagonal which offered more specific contact sealing areas.

Both types can be used with flanges having the standard ring joint flat bottom groove and held of

flanges by the specified amount, relying entirely on correctly applied initial bolt load for the proper

operation in service. Gasket metal should be selected to suit the service condition and should be of

Hardness lower than the flange metal. The annealing process of the metal is carefully controlled to

keep the hardness of the gasket below the maximum allowable hardness to ensure proper flow and

sealing without damaging the flange surfaces.

Download spec sheet here.

Metal Jacketed

Comprised of a soft pliable filler core surrounded by a metal jacket which may totally or partially enclose the filler.

Description

These gaskets are designed and widely used for heat exchangers, pressure vessels, gas mains,

valve bonnets and similar services. This metal jacket provides the mechanical strength to contain

the filler and is selected from material which is suitable to resist chemical attack from the fluid

to be sealed and also the operating temperature.

Metal jacketed gaskets are available in a comprehensive selection of materials and are custom-

to clients specific design requirements and are almost without any size limitations.

A durable protective coating is applied on every soft iron gasket to resist rusting in storage.

Download spec sheet here.

Metal

Flat Metal Gaskets.

Description

Metal gaskets can be manufactured from any kind of metal as per the clients requirements.

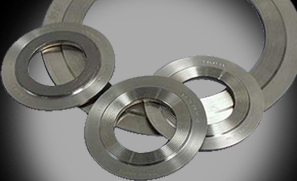

Ring Joints

Alternate plies of pre-

The metal winding of the gasket is formed into a Chevron configuration allowing superior resiliency

and self adjustment when compared to conventional gaskets, Spiral wound gaskets are available

to order in almost any combination of component materials.

The most common configuration is stainless steel 304 inner ring, Stainless steel 304 graphite winding

with carbon steel outer ring.

Download spec sheet here.

Spirals

CMG gaskets is a metal reinforced gasket which utilises a corrugated solid steel core, laminated with flexible graphite facing layers on both sides.

Description

Commonly used for heat exchangers and pressure vessels, Piping flanges, with pressure

ratings up to and including Class 300 / PN 40.

Pressure up to 40 Bar temperatures up to 450°C

Replacement for CAF

CMG’s has the following advantages:

Good blow-

Can be fitted to inner and/or outer cleats

The soft facing layer prevents damage to the flange

Economically suitable for high temperatures

Easy to handle and install

Download spec sheet here.

CMG

MRG gaskets is a metal reinforced gasket which utilises a corrugated solid steel core, laminated with flexible graphite facing layers on both sides..

Description

Standard core materials are carbon or austenitic stainless steel. Exotic alloys can be used to suit

Particular applications.

The graphite sealing layers can also be substituted with other soft facing materials such as

PTFE, Mica or compressed non-

MRG gaskets can be produced in any shape and are ideal for rectangular gaskets, or heat exchanger

gaskets with complex pass partition bar configuration. The low load requirements on the MRG

gasket make them ideal replacements for compressed asbestos fibre gaskets and metal jacketed

gaskets in heat exchanger applications.

Download spec sheet here.

MRG

Camprofiles are a composite gasket, which utilises a serrated metal core with a soft facing material. .

Description

Camprofiles have a wide range of seating stresses under which the seal is effected and

maintained. It can be used when there is insufficient bolt load to seal conventional gasket materials.

Easy to handle and fit. Suitable for a wide range of operating conditions.

The soft facing layer prevents damage to the flanges, provides a high integrity seal including

thermo cycling and shock loading conditions. Can be refurbished with a new facing layer and

reused. Camprofiles can be manufactured in a very wide variety of sizes and shapes according

to customer design requirements.

Download spec sheet here.

Camprofiles

Aluminium shims are a corrosion resistant option and ideal for a variety of industries and applications. .

Description

Aluminium is remarkable for its ability to resist corrosion due to the phenomenon of passivation

and for the metal’s low density.

While in general, aluminium has a very good corrosion resistance in most environments, different

alloys of aluminium results in different levels of corrosion resistance and strength.

Using aluminium for your shims offers incredible corrosion resistance as well as light weight solutions.

Structural components made from aluminium and its alloys are vital to the aerospace industry and

very important in other areas of transportation and building.

Aluminium Shims

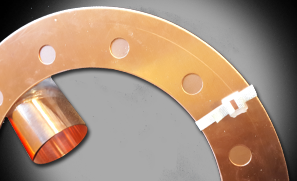

Copper is a highly ductile and malleable metal that is suitable for an array of applications.

Description

Copper is one of the most widely used metals for commercial purposes.

In its pure state sheet copper is easily bent by hand or hammered which is why it is often

used for gaskets.

Excellent for riveting, soldering and stamping and will not react with water or corrode easily.

The main features which give copper sheets its signature qualities can be categorised by the

alloy used, the hardness of the copper (temper), finish and gauge.

Copper